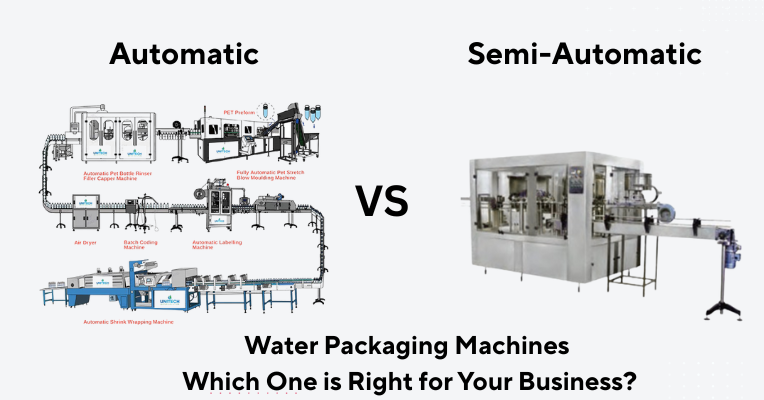

When setting up a water bottling plant, one of the most crucial decisions you’ll make is choosing between an automatic and a semi-automatic water packaging machine. The right choice can determine your production efficiency, cost savings, and long-term business growth.

At Unitech Water Solution, we understand how every business has unique needs. That’s why it’s important to understand the strengths and limitations of both machine types before making your investment. Let’s take a closer look at what each option offers and how to decide which one suits your business best.

Understanding Water Packaging Machines

A water packaging machine is designed to handle the process of filling, sealing, and labeling water bottles or pouches. It ensures hygiene, consistency, and accuracy in every package - something that’s critical for maintaining brand trust in the packaged drinking water industry.

These machines come in two main types:

- Automatic Water Packaging Machines

- Semi-Automatic Water Packaging Machines

While both serve the same basic function, they differ significantly in terms of operation, output capacity, cost, and maintenance requirements.

What Is an Automatic Water Packaging Machine?

An automatic water packaging machine performs the entire bottling process without much manual effort. From feeding empty bottles to filling, capping, labeling, and sealing - every step is automated.

These machines are ideal for large-scale operations or companies aiming for high production volumes. They ensure consistent packaging quality, reduce human error, and save significant labor costs in the long run.

Key Features of Automatic Machines

- High-speed filling and sealing process

- Integrated bottle washing, filling, and capping units

- PLC-controlled systems for precision

- Minimal human intervention

- Suitable for various bottle sizes and materials

Advantages

- Higher Production Efficiency:

Automatic systems can handle thousands of bottles per hour, making them ideal for medium to large water plants. - Superior Hygiene and Quality:

Since there’s minimal manual contact, the risk of contamination is very low. - Reduced Labor Dependency:

The system’s automation cuts down on manpower costs and improves consistency. - Long-Term Savings:

Although the initial investment is higher, the reduced operational costs and increased production output make it highly profitable over time.

Limitations

- Higher upfront cost

- Requires trained operators and regular maintenance

- Power consumption may be higher

What Is a Semi-Automatic Water Packaging Machine?

A semi-automatic water packaging machine combines manual and automatic operations. It automates certain steps - such as filling and sealing - but still requires operators to load or unload bottles manually.

These machines are perfect for small to medium businesses that are just starting or have limited production requirements.

Key Features of Semi-Automatic Machines

- Compact and easy to install

- Manual bottle loading/unloading

- Suitable for low-to-medium output

- Lower energy consumption

- Cost-effective initial setup

Advantages

- Budget-Friendly Option:

The lower initial investment makes it a great choice for startups or small bottling units. - Ease of Operation:

No need for highly skilled technicians - operators can easily handle the process after basic training. - Flexible Production:

Ideal for small-scale production or seasonal businesses with varying output needs. - Lower Maintenance Costs:

Fewer automated components mean simpler maintenance and less downtime.

Limitations

- Slower production speed compared to automatic machines

- More manual involvement, increasing the risk of minor inconsistencies

- Not suitable for large-scale operations

Key Factors to Consider Before Choosing

Before investing in a water packaging system, consider these essential factors:

1. Production Volume

If your business demands large-scale production - such as thousands of bottles per day - an automatic water packaging machine is the better choice. It ensures high output with consistent quality.

However, if your daily requirement is moderate or you’re just entering the bottled water market, a semi-automatic machine is a more cost-effective starting point.

2. Budget

Budget is a major deciding factor.

Automatic machines require a higher initial investment but deliver faster returns through increased production and efficiency.

Semi-automatic systems, while more affordable upfront, may need additional labor costs in the long run.

3. Workforce and Technical Skill

Automatic machines need trained personnel for operation and maintenance, while semi-automatic systems can be handled by general operators with minimal technical knowledge.

4. Space Availability

Automatic systems are larger and need more installation space. If your plant setup is compact, a semi-automatic unit might fit better initially.

5. Future Growth Plans

If you plan to scale your operations in the future, investing in an automatic water packaging system may be more strategic. It supports higher production without requiring multiple machines.

6. Maintenance and Energy Costs

Automatic machines usually have higher maintenance and energy demands, while semi-automatic ones are simpler and consume less power.

Which Machine is Right for Your Business?

To make the best decision, match the machine type to your business size and production goals:

|

Business Type |

Recommended Machine |

Reason |

|

Small-scale startup |

Semi-Automatic |

Affordable, easy to operate |

|

Medium-scale plant |

Semi-Automatic / Automatic |

Flexible depending on growth |

|

Large-scale plant |

Automatic |

High speed, consistent performance |

|

Seasonal or local supplier |

Semi-Automatic |

Low-cost, manageable production |

|

Established brand |

Automatic |

Fully automated efficiency |

Automatic vs. Semi-Automatic - A Quick Comparison

|

Feature |

Automatic Machine |

Semi-Automatic Machine |

|

Operation |

Fully automated |

Partially manual |

|

Production Speed |

High |

Moderate |

|

Labor Requirement |

Low |

Moderate to high |

|

Initial Cost |

High |

Low |

|

Maintenance |

Requires skilled staff |

Simple and affordable |

|

Ideal for |

Large-scale plants |

Small to medium units |

Why Choose Unitech Water Solution?

At Unitech Water Solution, we specialize in designing and supplying advanced water packaging machines that meet the needs of every business size - from local bottling startups to large-scale industrial plants.

Our machines are built with precision, durability, and energy efficiency in mind. Whether you choose an automatic or semi-automatic system, you can trust our technology to deliver:

- High-quality output

- Consistent filling and sealing performance

- Low maintenance requirements

- Long-term operational reliability

We also provide end-to-end support, including plant setup, machine installation, operator training, and after-sales service - ensuring a smooth and successful bottling operation.

Final Thoughts on Automatic vs. Semi-Automatic Water Packaging Machines

Choosing between an automatic and semi-automatic water packaging machine depends entirely on your production goals, budget, and future vision.

If you’re aiming for high-speed, large-scale production, an automatic machine is the way forward. But if you’re starting small or focusing on cost-efficiency, a semi-automatic machine can be a smart and sustainable beginning.

Whatever your decision, Unitech Water Solution is here to guide you at every step - helping you invest wisely in a machine that delivers the perfect balance of performance, quality, and value.