Introduction

Industries across India and worldwide face a growing challenge—access to clean, purified water for industrial processes. High TDS levels, chemical contamination, and inconsistent water quality can damage machinery, reduce product quality, and increase operating costs. This is where an Industrial RO Plant plays a critical role.

An Industrial RO Plant (Reverse Osmosis Plant) is a water purification system designed to remove dissolved salts, chemicals, heavy metals, and impurities from raw water sources such as borewell water, river water, or municipal supply. At Unitech Water, industrial RO plants are engineered to meet the specific water quality and capacity requirements of different industries.

In this guide, we will explain what an industrial RO plant is, its working principle, main components, and why it is essential for industrial applications.

What Is an Industrial RO Plant?

An Industrial RO Plant is a large-scale water treatment system that uses reverse osmosis technology to purify water for industrial use. Unlike domestic or commercial RO systems, industrial RO plants are designed to handle high water flow rates, high TDS levels, and continuous operation.

Key Functions of an Industrial RO Plant:

- Removes dissolved salts (TDS)

- Eliminates bacteria, viruses, and microorganisms

- Reduces hardness, heavy metals, and chemicals

- Produces high-quality purified water for industrial processes

Industries such as pharmaceuticals, textiles, food & beverage, power plants, chemical manufacturing, and packaging units rely heavily on industrial RO water treatment systems to maintain quality standards.

Why Do Industries Need an Industrial RO Plant?

Industries require water not just in large quantities but also in consistent quality. Untreated water can cause:

- Scaling in boilers and heat exchangers

- Corrosion of pipelines and equipment

- Product contamination

- Higher maintenance and downtime costs

An industrial RO plant ensures:

- Stable water quality

- Longer equipment life

- Compliance with industry standards

- Reduced water and energy costs

This is why companies choose trusted manufacturers like Unitech Water for customized industrial RO solutions.

Working Principle of an Industrial RO Plant

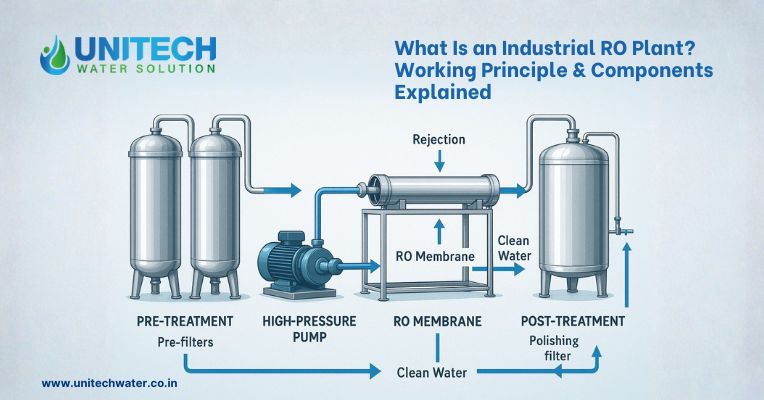

The working principle of an industrial RO plant is based on reverse osmosis, a membrane-based water purification process.

What Is Reverse Osmosis?

Reverse osmosis is a process where pressure is applied to force water through a semi-permeable membrane, allowing pure water molecules to pass through while rejecting dissolved salts and contaminants.

Step-by-Step Working Process:

1. Raw Water Intake

Raw water from sources like borewell, river, or municipal supply is collected in a raw water tank. This water may contain high TDS, turbidity, iron, chlorine, and other impurities.

2. Pre-Treatment Process

Before water enters the RO membrane, it passes through pre-treatment units to protect the membrane and improve efficiency. This step removes suspended solids, chlorine, and hardness-causing minerals.

3. High-Pressure Pump

A high-pressure pump increases the pressure of pre-treated water. This pressure is essential to overcome natural osmotic pressure and push water through the RO membrane.

4. RO Membrane Filtration

The heart of the industrial RO plant is the RO membrane. Under high pressure:

- Pure water passes through the membrane

- Dissolved salts and impurities are rejected as concentrate (reject water)

5. Permeate & Reject Water

- Permeate water: Purified water collected for industrial use

- Reject water: Concentrated impurities discharged or recycled

6. Post-Treatment (Optional)

Depending on the application, post-treatment like UV disinfection, pH correction, or mineral dosing may be added.

Main Components of an Industrial RO Plant

Understanding the components of an industrial RO plant helps industries choose the right system and maintain it efficiently.

1. Raw Water Storage Tank

Stores incoming water and ensures continuous supply to the RO system.

2. Multimedia Sand Filter (MSF)

Removes suspended solids, sand, silt, and turbidity from raw water.

3. Activated Carbon Filter (ACF)

Eliminates chlorine, organic matter, color, and odor that can damage RO membranes.

4. Water Softener (Optional)

Reduces hardness by removing calcium and magnesium, preventing membrane scaling.

5. Cartridge Filter

A micron filter (usually 5 microns) that removes fine particles before water enters the RO membrane.

6. High-Pressure Pump

Provides the required pressure for effective reverse osmosis operation.

7. RO Membrane Housing & Membranes

Houses high-quality RO membranes that perform the actual purification process.

8. Control Panel

Includes PLC or semi-automatic controls for system operation, pressure monitoring, and safety alarms.

9. Flow Meters & Pressure Gauges

Monitor water flow, pressure, and system performance.

10. CIP System (Clean-in-Place)

Used for chemical cleaning of RO membranes to maintain efficiency and lifespan.

At Unitech Water, all components are selected based on water quality analysis and industrial requirements.

Types of Industrial RO Plants

Industrial RO plants can be customized in various configurations:

- Single Pass Industrial RO Plant

- Double Pass Industrial RO Plant

- High Recovery RO Plant

- Automatic & PLC-Based RO Plant

- Containerized Industrial RO Plant

Each type serves specific industrial needs, depending on purity levels and recovery requirements.

Applications of Industrial RO Plants

An industrial RO plant is used across multiple sectors:

- Pharmaceutical manufacturing

- Textile and dyeing units

- Food & beverage processing

- Power plants and boilers

- Chemical and fertilizer industries

- Paper and pulp industry

- Electronics and semiconductor manufacturing

Unitech Water designs application-specific RO systems to ensure optimum performance.

Advantages of Using an Industrial RO Plant

- Consistent high-quality water

- Reduced equipment maintenance

- Lower operating costs

- High efficiency for high TDS water

- Environment-friendly water treatment

- Scalable capacity options

How to Choose the Right Industrial RO Plant?

Before selecting an industrial RO plant, consider:

- Raw water TDS and source

- Required water output capacity (LPH / KLD)

- Recovery rate and water wastage

- Automation level

- Maintenance and service support

A professional manufacturer like Unitech Water conducts water analysis and provides a customized solution rather than a standard system.

Conclusion

An Industrial RO Plant is an essential investment for industries that depend on clean and reliable water for production processes. Understanding its working principle and components helps industries make informed decisions and achieve long-term cost savings.

With advanced technology, high-quality components, and customized designs, Unitech Water delivers efficient and reliable industrial RO water treatment solutions tailored to diverse industrial needs.

If you are planning to install or upgrade an industrial RO plant, choosing the right system and expert manufacturer is the key to sustainable water management.